Your Digital Interface To Hansa‑flex Via Edi And Bmecat

Electronic data interchange (edi) enables rapid transfer of standardised business data between companies. The edi interface between your and our merchandise management system enable you to manage all the steps in e-procurement even more efficiently. In addition to an edi connection, hansa‑flex can also offer you the possibility of integrating specific hansa‑flex articles using bmecat into your familiar purchasing portal.

Electronic data interchange for major customers

EDI makes data interchange for e-procurement between different companies easier and ensures quicker and fewer errors in your goods procurement processes.

Setting up an EDI interface to HANSA‑FLEX

As part of a long-term partnership, HANSA‑FLEX offers customers with requirements such as complete supplier integration and closely integrated processes or very high data transfer volumes a connection to our EDI system. The complexity of programming EDI interfaces means that the service is available only to selected customers who, because of high sales volumes with HANSA‑FLEX, expend a lot of resources on managing their goods procurement processes. When setting up the EDI, HANSA‑FLEX can use standard formats for data transfer such as EDIFACT, ODETTE, VDA, X12 and XML as well as special solutions to meet your specific requirements.

Setting up of BMEcat by HANSA‑FLEX

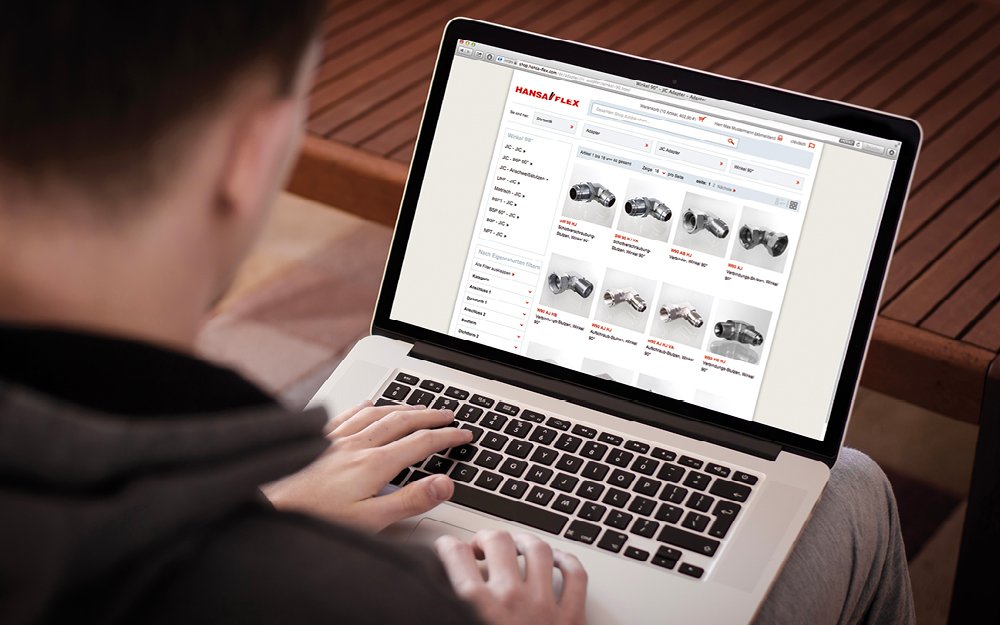

BMEcat is a standardised catalogue data exchange format in accordance with the guidelines of the Bundesverband Materialwirtschaft, Einkauf und Logistik e. V. The catalogue data are extracted from the product data system at HANSA‑FLEX and integrated into your company’s system. HANSA‑FLEX installs this technology for customers who wish to have digital product data and individualised requirements in their product catalogue. Another benefit is that you can continue to use your familiar purchasing portal from where you procure all special components and HANSA‑FLEX delivers the hydraulic or pneumatic components you have ordered directly to you.

Digital integration in three phases

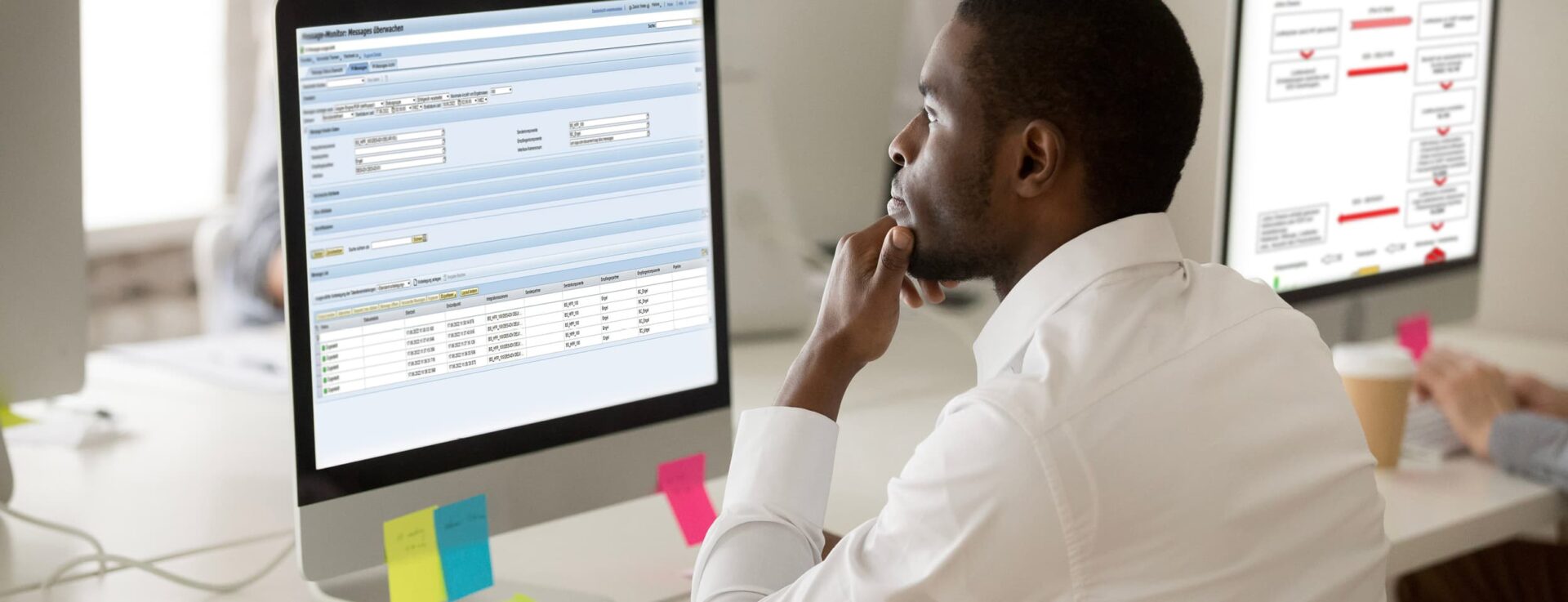

The implementation of an EDI can take a few days or several months, depending on its complexity. The installation process always takes place in three phases. During the first phase, the necessary parameters such as data format and version of the formatting standards are determined. Then there is an initial integration test and a very careful comparison of the master and material data sets between your company and HANSA‑FLEX. In the test phase, we perform extensive tests, which involves interchange of test data. In some cases, corrections have to be made and the comparison of material data repeated. The integration is completed with the go-live phase including monitoring of the data flow.

Edi is your direct hotline to hansa‑flex

The well trained team in the HANSA‑FLEX EDI Service sets up your digital interface optimally for your requirements, so that you can profit from all the advantages of rapid electronic data interchange.

Flexible mapping

If there is no suitable standard method, HANSA‑FLEX can configure your data format to your individual requirements.

Years of experience with EDI

The HANSA‑FLEX EDI specialists have decades of experience in this type of interface.

Scheduling delivery plans for the year

Using EDI, you can quickly and easily automate routine ordering processes in the medium or long term.

Save resources using EDI

Ordering via EDI significantly reduces the number of steps and paperwork costs in the ordering process.

Weitere serviceangebote von HANSA-FLEX

X-CODE hose identification system

X-CODE, the coding and identification system from HANSA‑FLEX, has been proven in practice millions of times. Each individual hose line is…

Find out moreOnline-Shop

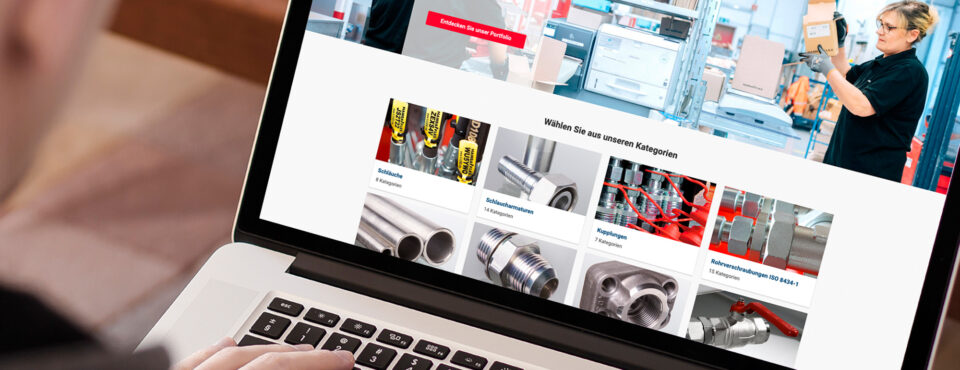

The HANSA‑FLEX online shop makes selecting and ordering products quick and easy. Over 80,000 articles are clearly listed in categories. The comprehensive…

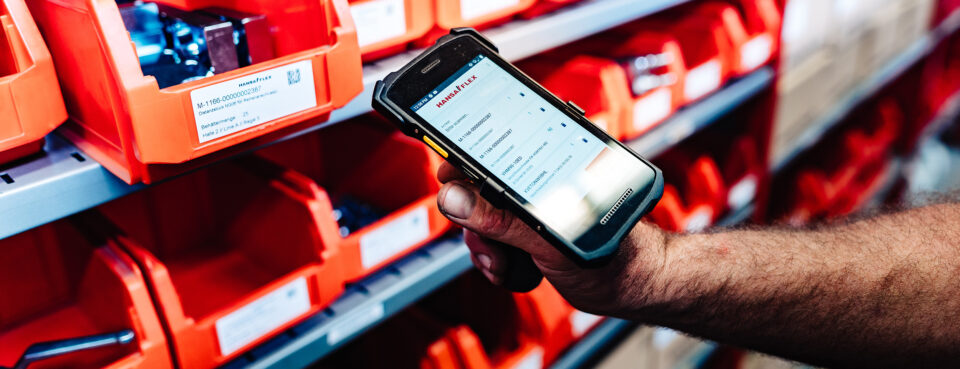

Find out moreScanner solutions

Yes, we scan! Scanner solutions from HANSA‑FLEX enable you to determine your goods requirement for fluid technology in the warehouse or on…

Find out more